Unlocking the Potential of Advanced Manufacturing: The Role of a China CNC Lathe Machining Parts Factory in Modern Metal Fabrication

Introduction to the Global Significance of CNC Machining in Metal Fabrication

The manufacturing industry is experiencing a paradigm shift driven by technological innovation, quality demands, and cost-effective solutions. Among the pivotal components of this transformation is the utilization of China CNC lathe machining parts factory services, which have become a cornerstone for enterprises seeking precision, efficiency, and scalability. As a specialized metal fabricator, these factories empower clients with state-of-the-art CNC machining capabilities that meet the rigorous standards of various industries including automotive, aerospace, electronics, and heavy machinery.

The Evolution of Metal Fabrication and the Rise of CNC Machining

Traditional metalworking, once reliant on manual operations, has evolved rapidly with the advent of Computer Numerical Control (CNC) technology. CNC machining transforms complex designs into precise, repeatable parts through automated control of machine tools. This leap in manufacturing technology has paved the way for china cnc lathe machining parts factory to provide unmatched accuracy, consistency, and throughput.

Why CNC machining is indispensable:

- Enhanced precision leading to high-quality finished products

- Reduction in manufacturing time and human error

- Ability to produce complex geometries and intricate designs

- Cost efficiency in large-scale production runs

- Flexibility to adapt to rapid prototyping and product modifications

Why Choose a China CNC Lathe Machining Parts Factory for Metal Fabrication?

The strategic move to collaborate with a china cnc lathe machining parts factory brings numerous advantages that can significantly improve your manufacturing outcomes and bottom line.

Unmatched Manufacturing Precision and Quality Control

Leading Chinese factories invest heavily in advanced CNC lathe machinery, which guarantees high precision and meticulous quality control processes. Strict adherence to international standards such as ISO 9001 ensures every part produced meets specifications with minimal variance.

Cost-Effective Production with Competitive Pricing

Leveraging China's large-scale manufacturing infrastructure reduces production costs substantially. Coupled with their expertise, factories can offer competitive pricing without compromising on quality, making them ideal for both small batches and large-volume orders.

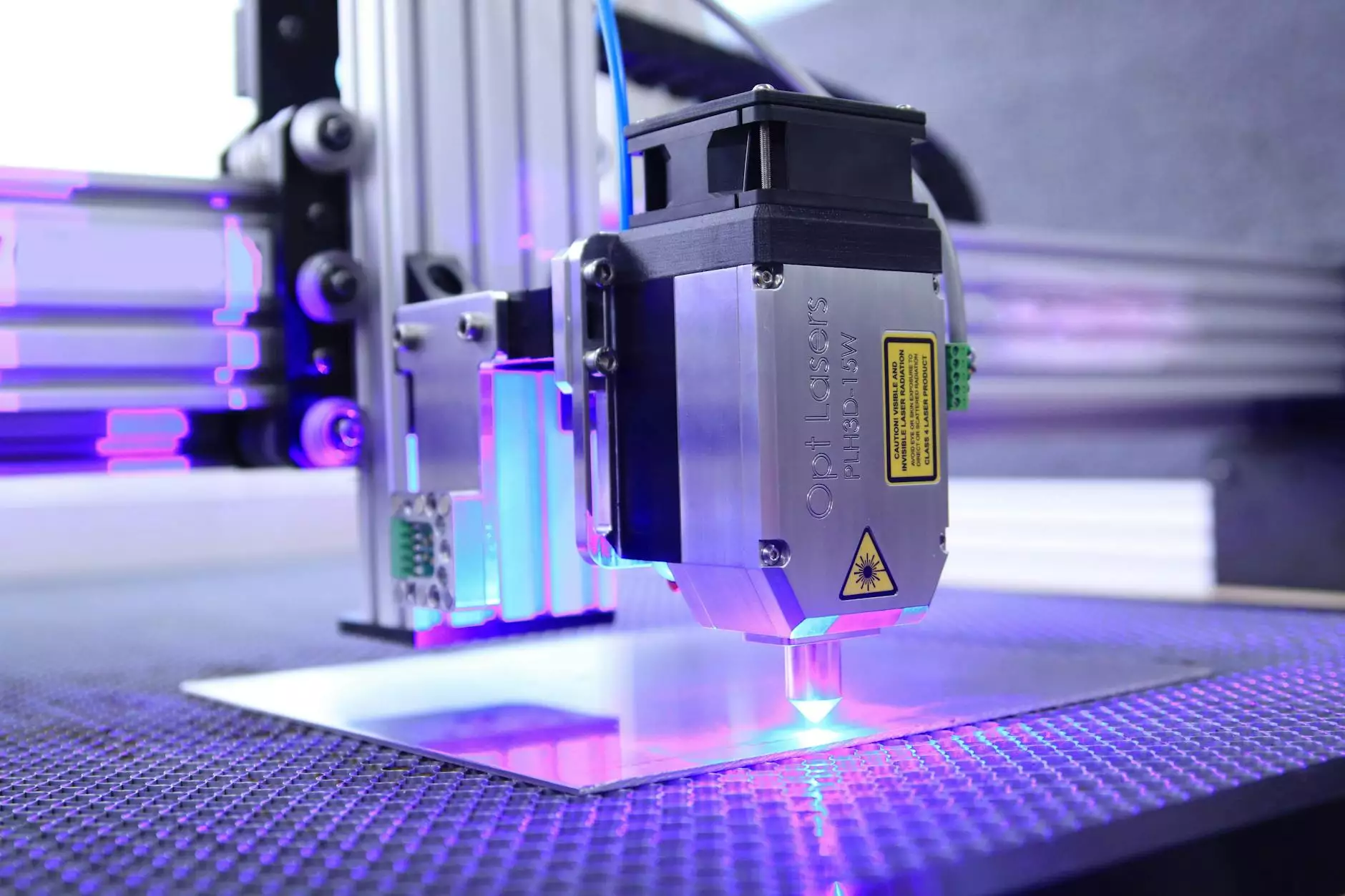

Advanced Technology and Equipment

A reputable china cnc lathe machining parts factory employs a wide array of modern CNC machines, including multi-axis lathes, high-speed tools, and robotic automation, enabling the production of complex and highly precise components.

Customization and Agile Manufacturing Capabilities

Modern Chinese factories excel in customization, efficiently translating client specifications into finished products. Their flexible manufacturing systems facilitate rapid prototyping, small batch production, and on-demand manufacturing, supporting innovation and time-to-market strategies.

Comprehensive Range of Metal Machining Services Offered by China CNC Lathe Machining Parts Factory

Whether dealing with ferrous metals, non-ferrous alloys, or specialty materials, a skilled china cnc lathe machining parts factory provides a diverse set of machining services, including:

- Precision CNC Turning: For cylindrical, conical, and complex round parts with tight tolerances.

- Multi-Axis Machining: Enables complex geometries and intricate internal features.

- Surface Finishing: Including polishing, anodizing, and coating for enhanced durability and aesthetics.

- Engraving and Marking: For branding or identification purposes.

- Assembly and Testing: Integrated services for complete component manufacturing and quality assurance.

The Role of Material Selection in Achieving Superior Machined Parts

An effective china cnc lathe machining parts factory emphasizes material quality, which directly influences the performance, longevity, and functionality of the final product. The most common materials used include stainless steel, aluminum, brass, copper, and engineering plastics. Advanced factories often have extensive experience working with specialty alloys and composite materials for demanding applications.

Industries Benefiting from China CNC Lathe Machining Parts Factory Services

The versatility and precision of CNC machining make it indispensable across a multitude of sectors:

- Automotive: Production of engine components, transmission parts, and custom prototypes.

- Aerospace: High-precision aircraft parts that meet safety and performance standards.

- Electronics: Enclosures, connectors, and thermal management components.

- Medical Devices: Implants, surgical tools, and diagnostic equipment parts.

- Industrial Machinery: Custom machine components and wear-resistant parts.

How a China CNC Lathe Machining Parts Factory Ensures Quality and Reliability

Quality assurance is at the heart of every reputable china cnc lathe machining parts factory. They implement comprehensive quality management systems, utilize advanced inspection equipment such as coordinate measuring machines (CMM), and adhere to strict testing protocols to guarantee each product conforms to industry standards and client specifications.

Additionally, they maintain transparency with clients through detailed documentation, real-time updates, and flexible communication channels, fostering trust and long-term partnerships.

Environmental Sustainability and Ethical Manufacturing Practices

Leading Chinese factories are increasingly committed to sustainable manufacturing practices. This includes waste minimization, energy-efficient operations, and compliance with environmental regulations, contributing not only to ecological preservation but also to brand reputation for their clients.

Partnering with a China CNC Lathe Machining Parts Factory: What to Consider?

To maximize the benefits of collaboration, it is essential to select a factory with:

- Extensive experience and proven track record in metal fabrication

- Advanced machinery and skilled engineers

- Robust quality management systems

- Transparent communication and responsive customer support

- Competitive pricing with clear quotations

- Ability to meet delivery deadlines consistently

Conclusion: Elevate Your Manufacturing with a Top-Tier China CNC Lathe Machining Parts Factory

Engaging with a china cnc lathe machining parts factory represents a strategic advantage for businesses aiming to enhance their product quality, reduce costs, and accelerate time-to-market. With their cutting-edge technology, rigorous quality controls, and comprehensive service offerings, these factories stand at the forefront of modern metal fabrication, ready to support diverse industry needs.

For companies seeking reliable, high-precision CNC machining solutions, recognizing the value of partnering with a reputable Chinese manufacturer is an essential step toward achieving manufacturing excellence and competitive differentiation in today’s dynamic global market.

Explore more about how a china cnc lathe machining parts factory can transform your production line by visiting deepmould.net — your trusted partner in advanced metal fabrication services.